Some Of Laser Cutting Services

Some Of Laser Cutting Services

Blog Article

In terms of modern day production, the precision and efficiency of laser reducing engineering are really activity-shifting. Laser cutting equipment have revolutionized industries by giving a technique of reducing supplies with unparalleled precision. When you’ve at any time marveled with the intricate types on metal or questioned how advanced styles are made so seamlessly, it’s generally the function of an industrial laser slicing device.

Enable’s begin with the basic principles: a laser cutter is actually a Instrument that employs a laser beam to cut elements. This beam is amazingly centered and generates high temperatures to melt or vaporize the material, making precise cuts. Unlike traditional techniques, which could use mechanical blades, a laser cutter provides a level of precision that is almost unmatched. Think about endeavoring to carve a delicate sample that has a hammer—Obviously, a laser cutter is a great deal additional refined!

Industrial laser chopping requires this technological know-how to the next degree, giving remedies for big-scale operations. These machines are built to deal with significant supplies and superior generation volumes, making certain that even by far the most demanding projects are accomplished with significant efficiency. Consider it as the difference between utilizing a precision knife for sensitive paper crafts and a strong observed for chopping by thick wood.

Not known Details About Cnc Laser Cutting

In the world of CNC laser slicing, the “CNC” stands for Computer system Numerical Manage. This technological innovation permits automatic and extremely precise cuts by subsequent electronic patterns. If you’ve ever made use of a pc to attract after which you can found that drawing arrive at everyday living, CNC laser reducing performs in an analogous way, translating digital styles into Actual physical cuts. It’s like having a Digital designer with the precision of the laser.

In the world of CNC laser slicing, the “CNC” stands for Computer system Numerical Manage. This technological innovation permits automatic and extremely precise cuts by subsequent electronic patterns. If you’ve ever made use of a pc to attract after which you can found that drawing arrive at everyday living, CNC laser reducing performs in an analogous way, translating digital styles into Actual physical cuts. It’s like having a Digital designer with the precision of the laser.Not known Details About Sheet Metal Laser Cutter

Precision laser cutting is not really pretty much creating cuts; it’s about generating them ideal every single time. The laser is usually modified to realize different depths and widths, making sure that every Lower is exactly where it must be. That is vital for apps where by even a slight deviation may lead to substantial concerns. Imagine it to be a surgeon’s scalpel, where by precision is not just critical but Completely important.

Precision laser cutting is not really pretty much creating cuts; it’s about generating them ideal every single time. The laser is usually modified to realize different depths and widths, making sure that every Lower is exactly where it must be. That is vital for apps where by even a slight deviation may lead to substantial concerns. Imagine it to be a surgeon’s scalpel, where by precision is not just critical but Completely important.Laser cutting products is available in different types, Every single personalized to unique requires. Regardless of whether You'll need a small desktop model for interest jobs or an enormous industrial device for manufacturing facility use, there’s a laser reducing solution around for yourself. These equipment change in electricity, speed, and capabilities, so it’s essential to pick the correct just one on your individual application.

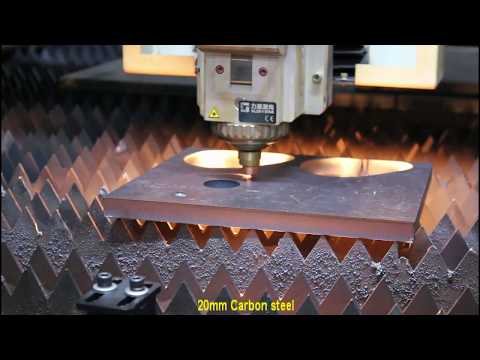

Sheet metallic laser cutters can be a Exclusive class of laser cutting equipment designed specifically for chopping metal sheets. They may be broadly used in industries ranging from automotive to aerospace because of their capability to deal with metallic with precision and pace. Photo a sheet of metal similar to a blank canvas, as well as laser cutter since the artist who produces intricate and delightful designs with remarkable precision.

Laser cutting products and services are One more critical element of this technologies. Not All people requires to speculate in their own personal laser chopping equipment, especially if they only require occasional cuts or absence the Room for these types of tools. Many businesses provide laser chopping solutions where you can send out your models and also have them Slice with significant precision. It’s like outsourcing your artwork to a talented explore here Skilled.

Laser cutting methods integrate different elements to provide the desired benefits. In the laser supply into the slicing mattress, along with the Management computer software, each A part of the program functions together to be certain a flawless Procedure. It’s a tad like a symphony orchestra, in which each musician has a particular role, and only by Doing work with each other do they produce a harmonious general performance.

In terms of laser chopping know-how, the evolution has been fast and impressive. Originally applied primarily for cutting metals, these equipment now tackle a wide range of materials including plastics, Wooden, and in many cases fabrics. This versatility makes laser cutting know-how a worthwhile Device in plenty of industries. Consider having a Swiss Army knife that could handle nearly any substance—This is often what modern laser slicing technologies gives.

The accuracy of laser cutting equipment is truly exceptional. They will Slash elements to within microns from the click through intended design, making sure that even one of the most intricate information are preserved. This standard of precision is especially worthwhile in industries exactly where exact measurements are important. Think about it given that the distinction between a tailor-made suit and off-the-rack apparel—the suit is simply excellent anytime.

The smart Trick of Cnc Laser Cutting That Nobody is Discussing

A different advantage of laser slicing technology is its performance. Contrary to conventional cutting strategies Which may have to Laser Cutting Technology have a number of steps or equipment, laser reducing normally completes the undertaking in one go. This don't just accelerates creation but in addition lessens material squander. It’s like having a high-speed educate that gets you for your desired destination swiftly and proficiently with no unneeded stops.In the context of industrial programs, the robustness of laser slicing equipment is vital. These devices are crafted to endure the demands of continuous Procedure, usually jogging 24/seven in significant-quantity settings. Their sturdiness assures reliable effectiveness and reliability, which happens to be important for protecting generation schedules. It’s like aquiring a major-responsibility truck that reliably provides products day after day.

One of the exceptional facets of laser cutting is its capacity to generate cleanse and exact edges. This reduces the necessity for write-up-processing, such as sanding or finishing, which can be time-consuming and dear. The end result is really a easy, completed product that often needs negligible more do the job. Envision ending a craft challenge without glue spills or rough edges—it’s that clear!